Common hopper forms of bucket elevators:

(1) Cylindrical bucket: With a large depth, it is used for conveying granular materials that are dry, have good flowability, and can be easily scattered.

(2) Shallow bucket: small depth, used for moist and flowing granular materials.

(3) Sharp angled bucket: Its side wall extends to the outside of the bottom plate, becoming a blocking edge. When unloading, the material can be discharged along the groove formed by the blocking edge and bottom plate of a bucket, suitable for transporting viscous and heavy block materials.

The hopper of the bucket elevator can be made of different materials. For example, steel plate welding can be used (commonly 2-6mm thick steel plates), nylon and polypropylene mold casting can also be used, or malleable cast iron can be used for manufacturing.

Generally, hoppers made of malleable cast iron are used for centrifugal discharge elevators. The hopper made of welded steel plates is used for gravity unloading elevators.

The different types of hoppers are described as follows:

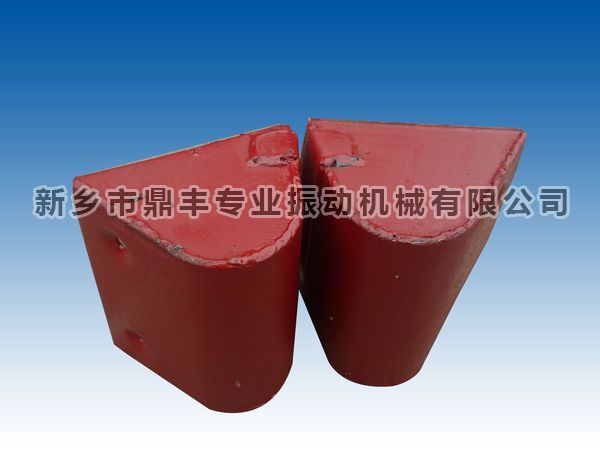

Malleable iron hopper: The commonly used hopper types are A or AA, and the bottom of the hopper is a cast round bottom. The AA type hopper has a reinforced extraction edge, which increases manufacturing costs but results in a longer service life. Compared with Type A, Type B hopper has a lower front edge, which is conducive to conveying rough, crushed or highly abrasive materials, such as coke, ore, stone and other similar materials on inclined bucket elevators. The leading edge of the C-type hopper is flat, suitable for conveying materials that may stick and accumulate in other types of hoppers. Other standard models of hoppers and designs are provided by the manufacturer.

Steel plate welding hopper: The hoppers are densely installed one after another on a chain or tape, so that the back of the previous hopper can serve as a discharge guide for the next hopper. The selection of hopper type mainly depends on the properties of the material and the inclination angle of the bucket elevator. Special sizes and forms of hoppers can be manufactured according to the requirements of the purchase order.