Steel wire compression spring (compression spring) is a vulnerable component that must be used on both linear and rotary vibrating screens. With good rebound force during equipment vibration, it can better bounce materials on the screen surface for effective screening.

The steel springs on the linear sieve are all subjected to high-temperature quenching treatment, making them more durable and less prone to deformation. The materials used in it are mostly circular in cross-section, and the springs are generally of equal pitch. There is a certain gap between the coils of the compression spring, and when subjected to external loads, the spring contracts and deforms, storing deformation energy. The springs on the vibrating screen are all made of high-quality galvanized spring steel, which is not easy to rust, has good elasticity, and has a long service life.

Vibration reducing steel wire spring is a commonly used elastic component, widely used in various vibration equipment, with advantages such as good stability, low noise, good isolation effect, and long service life.

Vibration spring is a mechanical component that uses elasticity to work. It is generally made of spring steel and is used to control the movement of mechanical parts, alleviate impact or vibration, store energy, measure the magnitude of force, etc. It is widely used in machines and instruments.

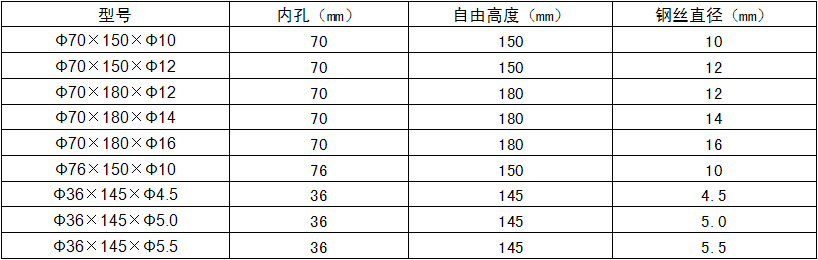

Partial steel spring specifications: