Product Overview of Dingfeng Vibration Platform in Xinxiang City:

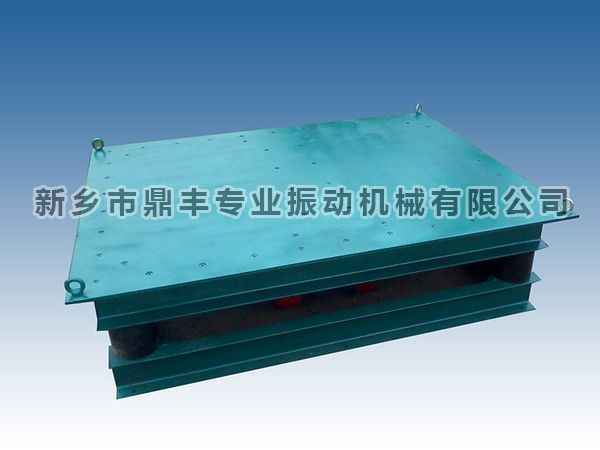

Vibration platform, also known as vibration consolidation platform. During the use of the vibration platform, the desired form of materials on the platform can be achieved by adjusting the excitation force of the vibration motor. This machine is mainly used for molding resin sand and lost foam molds. It drives the machine body to vibrate through a vibration motor to fully compact the sand and fill the mold. It can be combined with roller conveyors to form a continuous production line. The vibration platform is used in the production process to transform granular and powdery materials from bulk to block, shape, and other forms. The tabletop and machine base of the vibration platform are connected by air springs, resulting in low noise and good vibration reduction effect during operation. Has good processability and environmental friendliness. Vibration platforms are widely used in industries such as metallurgy, molds, food, chemicals, and building materials.

The Dingfeng vibration platform in Xinxiang City is a non-standard product that can be designed according to customer requirements. Select the appropriate vibration motor based on the load-bearing capacity of the vibration platform.

Composition of vibration platform:

1. The vibration platform mainly consists of four parts: bracket, tabletop, vibration mechanism, and shock absorber mechanism. Under the driving force of the vibration mechanism, it performs three-dimensional vibrations such as horizontal, vertical, and vertical, hence its name.

2. The vibration mechanism of the vibration platform is mainly composed of several vibration motors and transmission plates. The number of vibration motors is generally even, such as 4, 6, 8, 10, etc. The model of the vibration motor determines the main technical parameters of the three-dimensional vibration platform.

3. The damping mechanism of the vibration platform is mainly composed of damping springs, which are divided into several types such as rubber springs, composite springs, and inflatable springs

Characteristics of vibration platform:

1. High power, large tabletop; Power of 7.5kw, excitation force of 80KN, capable of carrying a sand box weight of 8T.

2. The tabletop height is adjustable and suitable for use on assembly lines.

3. Three dimensional vibration, suitable for complex cavity castings.

4. Continuously variable transmission, during the styling process, it can achieve the best compaction effect without damaging the model.

5. The self-locking function ensures accurate positioning on the production line.

remarks:

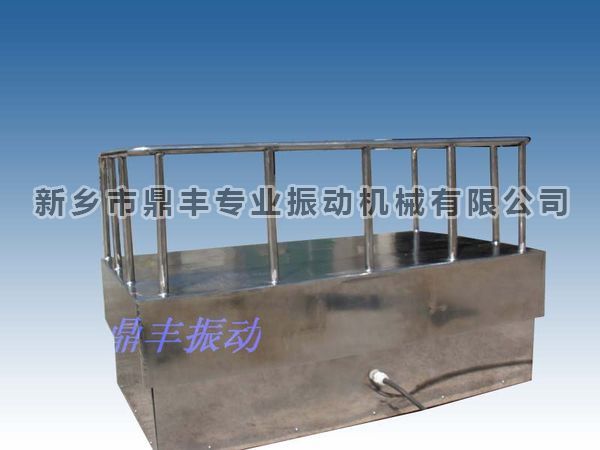

The above vibration platform pictures are products ordered by Hebei Jiheng Pharmaceutical for barrel vibration compaction of exported drugs. The main principle is that after screening, the flowability of the barrel powder is too strong, and it will automatically overflow when loaded into the barrel. In order to ensure the quality of the barrel, it is made of all stainless steel, and stainless steel guardrails are added to the table to prevent the barrel from moving back and forth during the vibration process. Multiple barrels can also be placed to achieve higher efficiency.