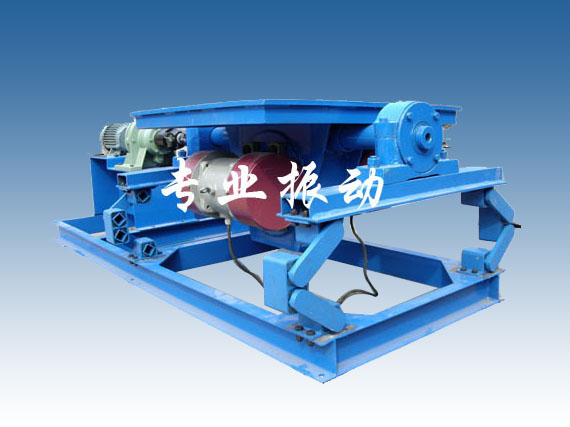

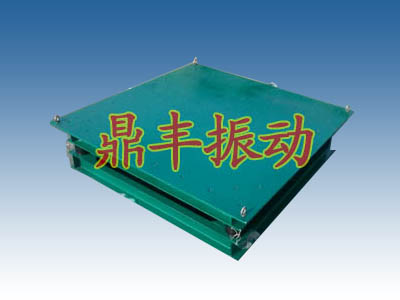

This vibration platform is a new type of vibration device mainly used in industries such as metallurgy and casting. It can play a role in cleaning, mixing, and compacting in the production process.

The flip type vibration platform mainly has the following characteristics:

1. Low price, only 10% of similar foreign products;

2. The machine base adopts channel steel, bent structure, sturdy and beautiful;

3. Adopting foreign elastic support, the lifespan is doubled;

4. Flip freely and vibrate smoothly.

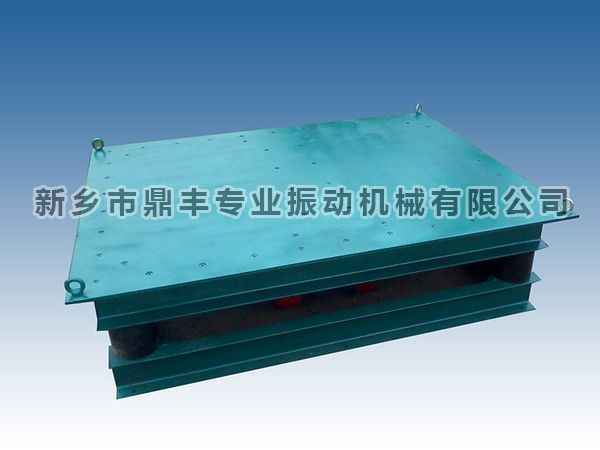

Use and maintenance of flip type vibration platform:

When flipping, the vibration motor should be careful not to collide with the moving parts on the test line;

2. The magnitude of the motor excitation force can be adjusted as needed during use;

3. Regularly check whether all fastening bolts are tightened during work. If there is a malfunction, stop working. When using, regularly add molybdenum disulfide to the vibration motor, once every two months;

4. The device should be safely grounded;

5. The universal joint should be kept level (after adding the workpiece and fixture to the platform).