Sealing rings are mainly used for the separation of mother and child grids and dust covers. Sealing rings are used to better seal the connection between the vibrating screen frame, prevent material leakage, and reduce the destructive force of the vibrating screen on the screen frame during vibration.

Sealing rings can be divided into rubber sealing rings, silicone sealing rings, polyurethane sealing rings, etc. according to their materials.

Rubber sealing ring is a widely used type of rubber product in sealing technology. Because rubber is a valuable elastic polymer material with a wide temperature range, it can undergo significant deformation under low stress in different media. This deformation can provide contact pressure, compensate for leakage gaps, and achieve the purpose of sealing.

Silicone sealing rings have a relatively high manufacturing cost, but they have excellent oil resistance, a long service life, and comply with national food and medical hygiene standards. They are commonly used for filtering and removing impurities from food, medicine, aluminum silver paste, and various oils.

Sealing rings can be divided into two types based on their shape: U-shaped and V-shaped.

Classification introduction of vibrating screen seals:

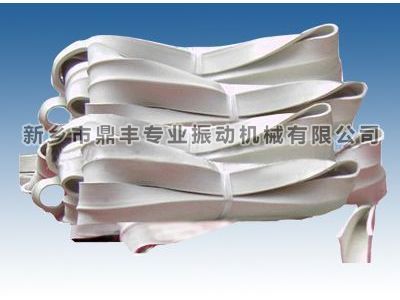

1. U-shaped seal: It has extremely strong plasticity, good elasticity, resistance to compression deformation, and aging. It is one of the essential accessories of the rotary vibrating screen (three-dimensional vibrating screen), mainly installed on the outer side of the grid and the mother and child screens, to provide sealing, buffering, shock resistance, anti slip, dust-proof and other issues.

U-shaped seals are classified by material: natural rubber, food grade silicone, high-temperature resistant silicone, polyurethane, and other materials. The models can be divided into: * 400, * 600, * 800, * 1000, * 1200, * 1500, * 1800, etc. Special models can be customized.

2. V-shaped seal: mainly installed on the bottom frame and vibrating body of the vibrating screen, as well as the sealing medium at the contact part between the upper frame of the vibrating screen and the dust cover. It mainly plays a role in sealing, buffering, and shock absorption. The seal has the characteristics of elasticity, insulation, impermeability, and air resistance.

V-shaped sealing strip: It is one of the important components in the vibrating screen, and like the screen mesh, it is a vulnerable part. If it is not frequently disassembled when installed on machinery, its service life is more than six months. The more frequently it is disassembled, the more likely it is to be damaged.

V-shaped sealing strips can be divided into materials such as rubber, silicone, polyurethane, etc. Rubber V-shaped sealing strip is a commonly used type, and the main characteristic of rubber is its low elastic modulus and high elongation. Silicone V-shaped sealing strips are mainly used in materials with high hygiene requirements and special characteristics such as high temperature, oily, corrosive, etc. in food, medicine, chemical industry, etc.