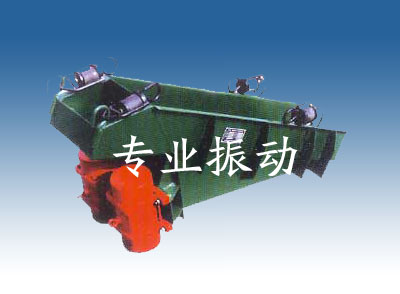

GZG series motor vibrating feeder

The GZG series motor vibrating feeder is a new type of feeding equipment developed by our company's engineering and technical personnel. It is widely used in industries such as mining, metallurgy, coal, building materials, chemical, power, and grain. It is used to uniformly, continuously, or quantitatively feed block, granular, and powdery materials from storage bins or other storage equipment to the receiving equipment, and is suitable for automatic batching, quantitative packaging, and automatic control. This product has small size, low noise, light weight, low power consumption, and easy installation and maintenance.

Main features of GZG series motor vibrating feeder

This vibrating feeder can adjust the excitation force to change and control the flow rate during use, making it easy to adjust, stable in flow rate, low in noise, low in power consumption, and no material flushing phenomenon. At the same time, this machine has the characteristics of light weight, small size, and easy maintenance. If it adopts a closed structure, it can prevent dust overflow and environmental pollution.

Main technical parameters of GZG series motor vibrating feeder

型号 | 生产率t/h | 给料槽尺寸宽*长*高mm | 运行方式 | 粒度mm | 振动电机 | 重量Kg | ||||

电压V | 频率Hz | 型号 | 功率KW | 振动频率次/分 | ||||||

GZG30-4 | 15 | 300*1000*160 | 连续 | 120 | 380 | 50 | YZD2.5-4 | 0.18*2 | 1450 | 110 |

GZG40-4 | 30 | 400*1200*160 | YZD5-4 | 0.25*2 | 155 | |||||

GZG50-4 | 50 | 500*1200*160 | YZD8-4 | 0.4*2 | 190 | |||||

GZG60-4 | 80 | 600*1800*180 | 180 | YZD16-4 | 0.75*2 | 410 | ||||

GZG70-4 | 100 | 700*1800*200 | 180 | TZP20-4 | 1.1*2 | 440 | ||||

GZG80-4 | 200 | 800*2000*225 | 200 | TZD32-4 | 1.5*2 | 640 | ||||

GZG90-4 | 300 | 900*1500*300 | 250 | YZD50-4 | 2.2*2 | 730 | ||||

GZG110-4 | 400 | 1100*1500*300 | 900 | |||||||

GZG130-4 | 500 | 1300*1500*400 | 350 | 1000 | ||||||

GZG70-6 | 80 | 700*1800*200 | 150 | YZD20-6 | 1.5*2 | 960 | 440 | |||

GZG80-6 | 160 | 800*2000*225 | 180 | YZD30-6 | 2.2*2 | 670 | ||||

GZG90-6 | 240 | 900*1500*300 | 240 | YZD40-6 | 3.0*2 | 740 | ||||

GZG110-6 | 320 | 1100*1500*300 | YZD50-6 | 3.7*2 | 940 | |||||

GZG130-6 | 400 | 1300*1500*400 | 320 | 1040 | ||||||

GZG150-6 | 500 | 1500*1800*500 | 2000 | |||||||

GZG180-6 | 800 | 1800*1800*500 | YZD75-6 | 5.5*2 | 2590 | |||||

ZG200-6 | 1000 | 2000*2000*500 | 360 | 3700 | ||||||

Installation and use of GZG series motor vibrating feeder

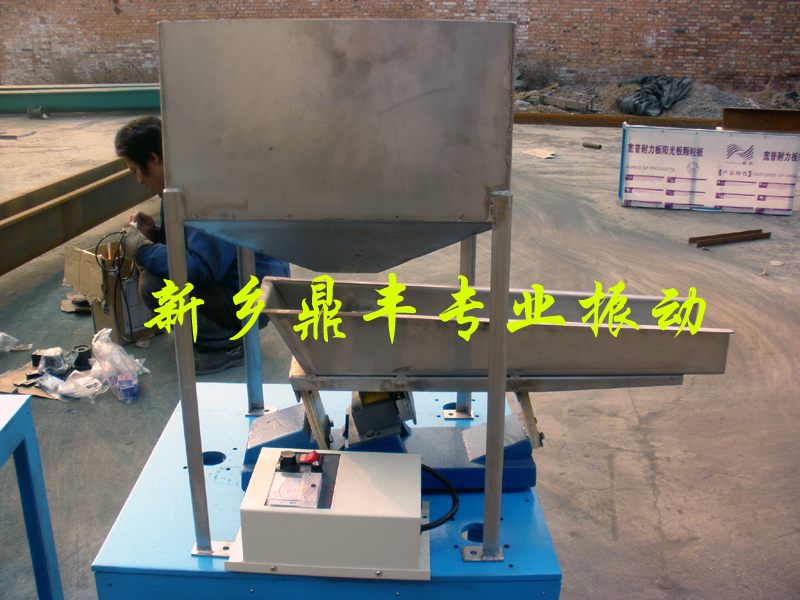

The GZG series vibrating feeder has two installation forms: hanging and seat.

The power supply for the two vibration motors of the GZG series vibrating feeder is three-phase 380V, 50Hz. Before the air freight test run, it is necessary to check whether the bolts in each part are tightened, especially the foundation bolts of the vibration motor. After continuous operation for 4 hours, the connecting bolts in each part should be re tightened once, and then tightened 2-3 times within a week.

When the vibration motor is running, the rotation directions of the two vibration motors should be opposite. During the air transport test run, check whether the feeder is running smoothly and pay attention to the temperature rise of the vibration motor bearings. After continuous operation for 4 hours, the high temperature of the bearings should not exceed 75 ℃.

GZG series motor vibrating feeder instruction

GZG series motor vibrating feeder can be made according to user needs:

Lower vibration type: The vibration motor is placed under the feeder;

Upward vibration type: The vibration motor is placed on top of the feeder;

Adjustable speed: The vibration frequency of the vibration motor can be infinitely adjusted within the range of 0 to rated frequency;

Open type: The top of the feeder is open, which is more suitable for downward vibration type;

Sealed type: The feeder is completely sealed except for the inlet and outlet ports;

Base type: For large (heavy) feeders, a base type structure is generally used.