The vibrating feeder is suitable for feeding systems in the metal and coal industries. By using a feeder, the material in the silo is evenly discharged onto the belt conveyor to form a material layer of appropriate thickness and width. The homework materials include coal, ore, sand and gravel, sandy soil, as well as powder particles from chemical plants and powder raw materials from food and drug factories.

Product Features

1. Can easily control the discharge capacity. Through the controller of the feeder or the electrical control system of the entire equipment, the discharge capacity (ton/hour) of the feeder can be proportionally increased or decreased by frequency conversion;

2. Wide range of applicable materials. Materials in different forms such as powder, granules, and blocks can be transported;

3. Low maintenance costs, due to the use of resonance principle, the feeder has the characteristics of low power consumption and minimal wear and tear;

4. Used for special working conditions. According to different working conditions, the feeder can be equipped with structural components such as dust covers, lining plates, seals, and water cooling sleeves;

5. Smooth vibration and reliable operation;

6. Special grid design to prevent material blockage;

7. The gap between the bars can be adjusted;

8. There are many wear-resistant parts;

9. Prevent wear-resistant parts from being worn by small materials, separate the small materials, and increase production;

10. Optional variable frequency speed motor can be installed to adjust the frequency and change the output, making it easy to control the feeding amount without the need to frequently start the motor.

Working principle

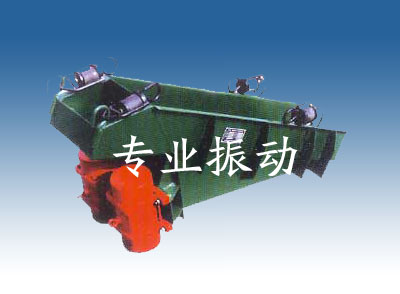

The vibrating feeder is mainly composed of a vibrating frame, springs, vibrators, motor vibrating frames, and motors. The exciter is composed of two eccentric shafts at specific positions that mesh with gears. During assembly, the two gears must mesh with each other according to the markings, and the two eccentric shafts are driven by a motor to rotate, thereby generating a huge synthesized linear excitation force. This force causes the body to vibrate forcibly on the supporting spring, and the material is driven by this vibration to slide and throw on the chute, thereby moving the material forward and achieving the feeding purpose. When the material passes through the sieve strip on the tank, smaller materials can fall through the gap between the sieve strips without going through the next crushing process, thus achieving the screening effect.

CLASSIFICATION

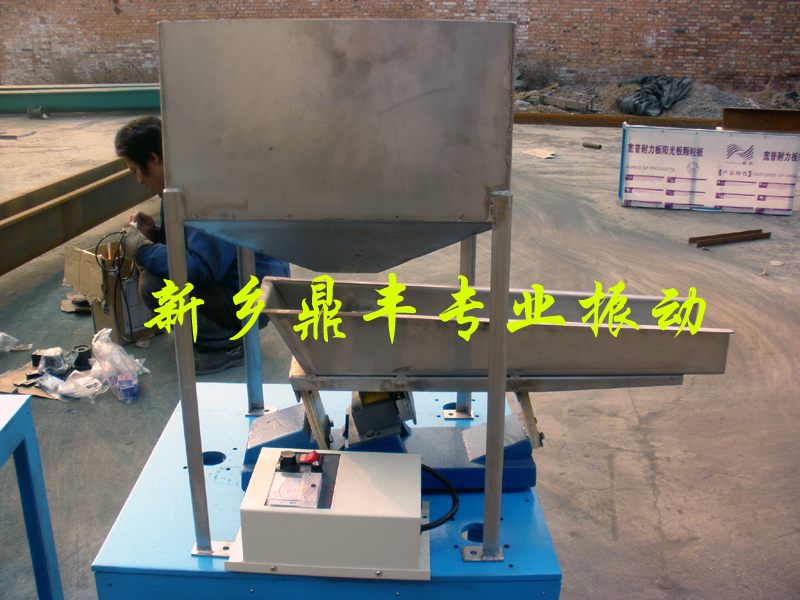

1. According to installation form: suspended and pedestal type

2. According to the principle of vibration: electromagnetic type, vibration motor type, eccentric block resonance type.

3. Electromagnetic feeder: The vibration source consists of an electromagnet and a spring plate. After the electromagnetic iron is excited by a pulse current, the material trough moves backward. At the same time, under the force of the spring plate, the material trough produces high-frequency movement forward and backward, allowing the material to be smoothly transported forward.

4. Vibration motor type: Several vibration motors are installed at the tail of the material tank, and the vibration motors generate vibration force when powered on.

5. Eccentric block resonance type: a combination of the vibration source generated by the rotation of the unbalanced block and the resonant rubber spring, powered by a motor. This form requires a smaller driving force, i.e. the power of the motor, but can achieve greater vibration force. Only the RFH type rubber spring feeder from Japan's Kobe Steel adopts this form.