Unloader is the main equipment for dust removal, air supply, and other equipment feeding, suitable for powdery and granular materials.

working principle:

Unloaders are divided into three categories: ordinary type, pressure resistant type, and high temperature resistant type. The unloader can be driven at a constant speed to continuously discharge materials at a controlled rate, or it can be driven at an indefinite speed and used as a feeder.

Ordinary type unloader: It can be used on materials below 150 degrees Celsius and at room temperature, and can continuously and uniformly feed into the conveying pipe. In the system and separation dust collection section, it can also serve as an unloader.

Unloader pressure resistant type: It adopts a closed rotor and can be widely used in suction type, pressure type airflow conveying systems, and negative pressure conveying equipment. The rotating unloader can ensure that the airflow pressure inside the conveying pipe does not leak, and can safely transport and collect materials. Therefore, it is called a universal air lock in this regard. It not only can withstand pressure, but also has ordinary functions.

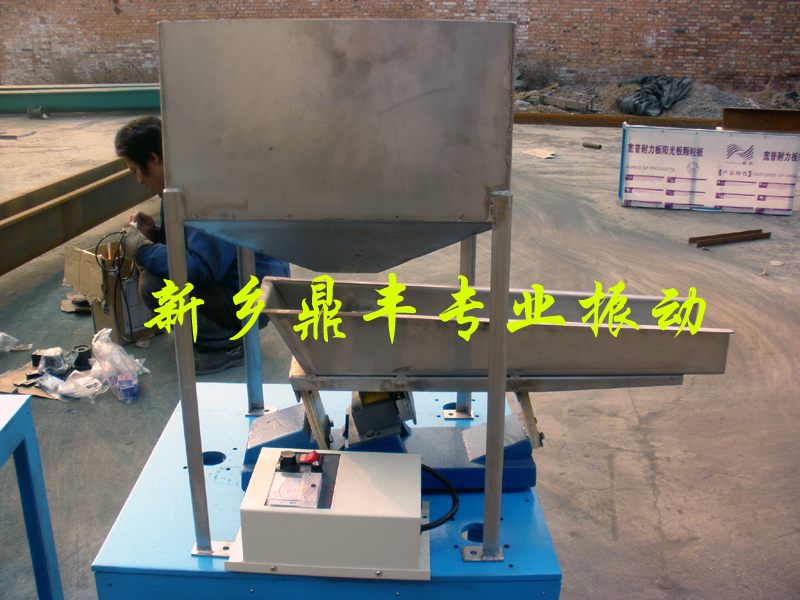

characteristic:

(1) The unloader adopts the principle of planetary rotation, with input and output on the same axis, and has the unique feature of being directly connected to the motor, resulting in a compact structure, beautiful and novel appearance, small volume, and light weight

(2) The unloader operates reliably and smoothly, with low noise, few faults, long service life, and the gear components are made of ductile iron and bearing steel Good performance and high wear resistance

(3) Bearings, gearboxes, away from the valve body, avoiding the influence of high temperature dust, good sealing performance of front and rear end caps, preventing dust leakage, and extending the service life of motor components and lubrication systems

(4) The unloader has strong overload capacity, low impact resistance inertia moment, and is suitable for frequent starting and reverse rotation