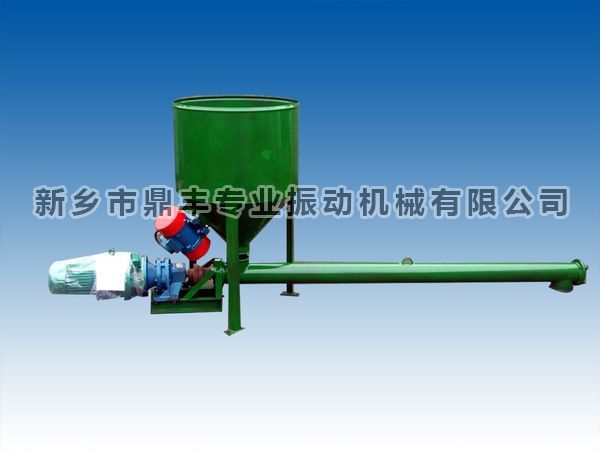

Working principle of double helix mixer:

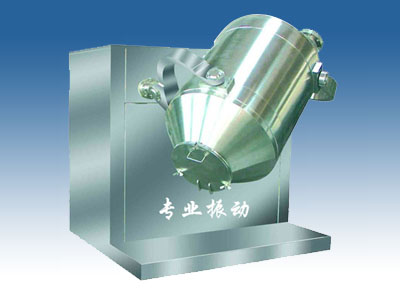

The screen of this equipment is cylindrical and placed inside the machine body. After passing through the spiral conveying system, the material is mixed with the airflow and atomized into the screen cylinder; By using the wind turbine blades inside the mesh tube, the material is simultaneously subjected to centrifugal force and cyclone propulsion force, thereby causing the material to spray through the mesh and be discharged from the fine material discharge outlet. Materials that cannot pass through the mesh tube are discharged from the coarse material discharge outlet along the wall of the mesh tube.

Characteristics of Double Spiral Mixer:

1. The whole machine has a small volume, light weight, smooth and vibration free operation, no noise, good sealing performance, no dust, and high efficiency;

2. The shell structure is novel, easy to install, and easy to control;

3. Can be used as a single machine or in combination with multiple machines, running continuously for a long time, safe and reliable;

4. The screen mesh is washed by the cyclone and can be automatically cleaned;

5. Has the ability to further break down agglomerated materials;

6. New outer spherical bearings extend the service life;

7. This machine can be matched with pneumatic conveying systems, directly connected to the air duct, saving resources;

8. New design: The gas protection system delivers purified air to both ends of the equipment, effectively reducing the temperature generated during operation; Forming a gas barrier layer on the bearing to prevent dust from entering, effectively extending the service life of the bearing, reducing maintenance frequency, and improving work efficiency;

9. Specially designed to meet specific needs.

Double helix mixer usage:

Used in industries such as metallurgy, mining, pharmaceuticals, food, chemicals, metal powders, and non-metallic materials.