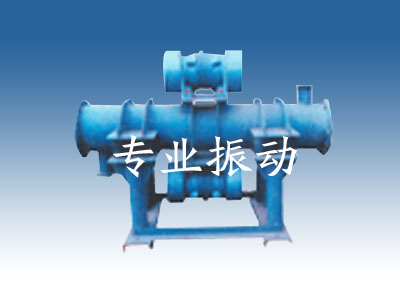

ZM vibration grinder product usage:

The ZM series vibration mill is a new type of high-efficiency powder milling equipment, with three structural types: single cylinder, double cylinder, and triple cylinder. Among them, the 2ZM series vibration mill has a wide range of applications. Vibration mill utilizes high-frequency vibration of a cylinder, and the steel ball or steel rod medium in the cylinder relies on inertial force to impact the material. The acceleration of the medium when impacting the material can reach 10g-15g. Therefore, it has the advantages of compact structure, small volume, light weight, low energy consumption, high output, concentrated grinding particle size, simplified process, simple operation, convenient maintenance, and easy replacement of lining medium. It can be widely used in industries such as metallurgy, building materials, mining, refractory, chemical, glass, ceramics, graphite, etc. for powder production.

Installation and adjustment

The motor bracket of this machine is welded onto the cylinder, and the motor is connected to the bracket with bolts. During installation, after leveling the frame, place the body of the grinder on the elastic support.

Before starting up this machine, the following tasks must be done:

1. Fill the machine with abrasive media, and do not turn it on without abrasive media to prevent the machine from being too light and causing a car accident.

2. This series of grinding machines uses vibration motors with low power and high vibration intensity. Generally, no dedicated electrical cabinet is configured. If there is a special need, it can be ordered separately.

3. If continuous automatic feeding and discharging are required, our factory can configure automatic feeding and discharging devices for users.

4. Depending on the material used for vibration grinding, the required vibration grinding strength also varies. Therefore, the excitation force can be adjusted by adjusting the angle of the eccentric block of the vibration motor.

use and maintenance

1. Before the series of grinding machines are officially put into operation, no materials are added (but grinding media must be filled), and a trial run of half an hour to two hours is conducted. After checking for accuracy, all fasteners are tightened again.

The performance of the vibration motor is one of the key factors affecting the performance of the grinding machine. Generally, high-temperature lubricating grease (such as heat-resistant grease produced by Yingkou Petrochemical Plant, with the label Liaoying Q327-82) should be added to the bearing chamber every 10-15 days; 7016 high and low temperature lubricating grease and 7019 high temperature lubricating grease produced by Yiping Chemical Plant. Open the motor bearing chamber every quarter, clean the bearings and bearing chamber, and during assembly, fill 40% -50% of the bearing chamber space with high-temperature grease.

To extend the service life of the lining, please change the direction of the drive motor every two months or so. (This clause is used for matching with ordinary motors)

4. The grinder should be overhauled once a year: a. Check the vibration motor bearings; b. Check the lining and various operating connections, and update them promptly if necessary.

5. Different materials with different requirements require different lining materials and grinding media materials. In order to ensure the performance of the whole machine and the quality of the vibration grinding product, the lining and grinding media of the vibration grinder should be made of specialized materials.

6. The feeding and discharging methods of the cylinder can be flexibly changed according to needs.

7. The use and maintenance of vibration motors must be strictly operated in accordance with the vibration motor user manual.