summary

The 2ZM series vibration mill is a new type of high-efficiency and energy-saving grinding equipment. It has significant advantages over traditional rotary mills in grinding fine and ultrafine powder materials. The machine has the advantages of high vibration intensity, high grinding efficiency, low power consumption, low noise, compact structure, and easy installation and maintenance, with an efficiency increase of 2-5 times and a 20% -30% reduction in energy consumption. This machine can be widely used in various industries such as mineral processing, building materials, grinding materials, powder metallurgy, electricity, ceramics, refractory materials, magnetic materials, chemical industry, food, etc. It is an ideal replacement product for ball mills.

structure and principle

This machine is mainly composed of a chassis, a body bracket, a soundproof cover, a body, a grinding cylinder, an exciter, a lining plate, an elastic support, a grinding medium, and a drive motor.

1. The chassis supports the body with elastic support and maintains the flexible connection distance between the driving motor and the vibrating body unchanged;

2. The soundproof cover is used to block the noise emitted by the grinder during operation, in order to reduce the impact of noise on the entire work area;

3. The body is fastened with a grinding cylinder and equipped with an exciter;

4. The grinding cylinder is the working body of the vibrating mill, used to contain the grinding medium and abrasive material;

5. The exciter is used to convert the rotational torque of the motor into periodic vibration of the mill;

6. The lining plate is tightly attached to the inner wall of the grinding cylinder to protect it. When vibrating and grinding materials inside the grinding cylinder, there is also significant wear on the inner wall of the grinding cylinder. Installing an easily replaceable lining plate inside the grinding cylinder can improve the service life of the entire machine;

7. Elastic support keeps the grinding machine body in an elastic state and effectively isolates the vibration impact on the base when the body vibrates;

8. The grinding medium is the grinding body of the grinder, used for impact grinding of materials;

9. Drive the motor to provide energy for the vibration grinding of the mill.

Connect the power supply and drive the motor to rotate the exciter through a flexible coupling, generating sufficient excitation force to cause the mill body to enter a cyclic vibration state. The oscillation force is continuously transmitted to all materials loaded into the grinding cylinder (i.e. the medium and the ground material), and through the mutual impact between the grinding medium and the ground material, the ground material is crushed and finely ground.

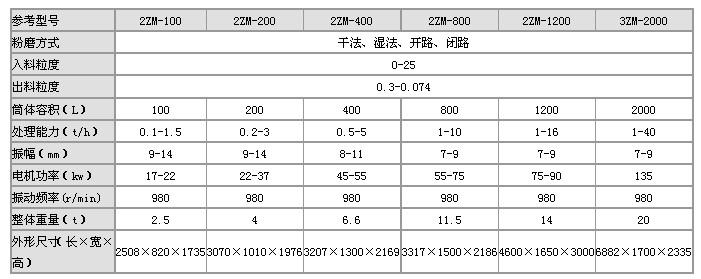

Main specifications and technical parameters

安装和调整

1.振动磨的底架应安装在水泥基础上,底架应找平找正。圆筒两侧支座下部的水平误差不得大于0.5mm,底架找平找正后,将地脚螺栓二次灌浆固定牢。安装所需要的地脚螺栓由用户自备。

2.振动磨安装好后,筒体在装入介质前,筒体的中心线应比电动机的中心线高8mm,筒体装入介质后,筒体的中心线应低于电动机的中心线11mm。

3.介质在圆筒中的填充率为65-75%,填充率过高或过低都不能得到**佳的粉磨效果。

4.激振器的冷却水路应并联。

5.振动磨运转时有噪音发生,为了降低环境噪音,应将振动磨用隔音罩密闭。

6.振动磨调整完毕后,应将隔音罩装好。各密封防尘部分和软连接接口应处于有效工作状态,如有损坏或失效,应立即处理或更换。

使用和维护

1.振动磨要求均匀加料,给料量应在试机时调整合适。振动设备上的固定螺栓容易松动,设备启动前应将各处的螺栓再检查紧固一次。

2.振动磨空车启动20秒后再向磨内给料。停机前先停止给料,约20秒后再停车。

3.振动磨中的介质是要磨损消耗的,当介质消耗掉10%-15%时,或感到出料粒度有变化时,应补充新的介质,按原先加入介质的**大尺寸加入,同时检查被磨细的介质,太细的要选出。

4.经常检查弹簧是否出现裂纹,一旦发现,应及时更换,以免运转中断裂而造成主机其他部分损坏。轴承应每周用油枪加油一次(2#或3#复合锂基脂)每个轴承每次补给量约0.1Kg,润滑脂量不要超过轴承室内容积的1/3-2/3。轴承**高温度不得超过75°C。