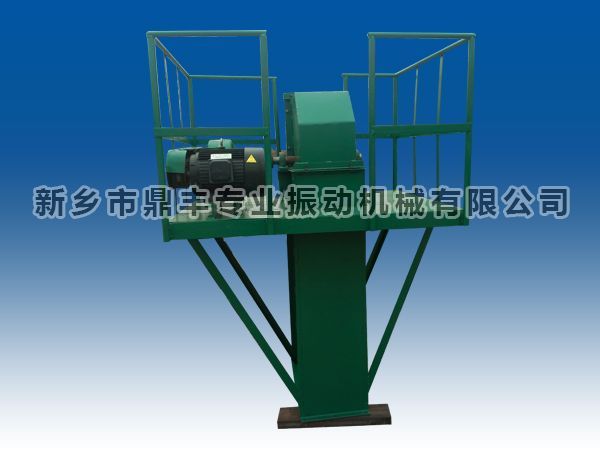

HL type bucket elevator

The TH and HL bucket elevators are suitable for vertically conveying powdery, granular, and small block materials with high grinding properties, such as grains, coal, cement, crushed ores, etc. The conveying height is 40m. Its characteristics are: simple structure, smooth operation, digging type loading, mixed or gravity unloading, and the wheel rim adopts a combination sprocket for easy replacement. The sprocket rim has a long service life after special treatment. If a gravity automatic tensioning device is used in the lower part, it can maintain a constant tension, avoid slipping or detachment, and at the same time, when the hopper encounters resistance, it has a certain tolerance to effectively protect the moving parts. The material temperature does not exceed 250 ℃. The TH type is designed and manufactured according to the JB3926-85 "Vertical Bucket Elevator" standard, and should be prioritized for use. Except for the connection dimensions, the chain, sprocket, and tensioning device of the HL bucket elevator are the same as those of the TH type.

Classification of bucket elevator models:

#TD/D type bucket elevator

#TH and HL bucket elevators

#NE series plate chain bucket elevator

Note:

1. The bucket capacity in the table is calculated, and the conveying capacity is calculated based on a filling coefficient of 0.6.

2. TH type bucket elevator hopper usage: zh - medium deep bucket: conveying wet and viscous materials, such as sugar, wet fine sand, etc.

SH deep hopper: Conveys powdered to small block materials such as cement, sand, coal, etc.

3. The use of HL type bucket elevator hopper: Q-shallow round bottom hopper: conveying wet, easy to agglomerate, difficult to throw out materials such as wet sand, wet coal, etc.

S-deep round bottom hopper: Conveys dry, loose, and easily thrown materials such as cement, coal chunks, crushed stones, etc.

4. Tension calculation: G=40+0.232Q * H in the formula: Q conveying capacity (t/h) H lifting height (mm) G tension (kg)