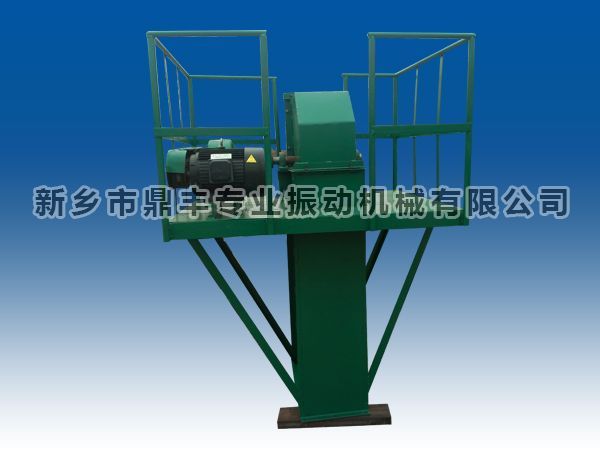

Motor vibration hoist

The motor vibration hoist uses a vibration motor as the vibration source, and utilizes the combined amplitude of the two vibration motors to transport the material upward along the spiral conveyor groove. DZC vertical conveyor is mainly used to lift granular, powdery, and block materials. This conveyor has a simple structure, easy maintenance, quantitative material delivery, and continuously adjustable conveying capacity. It can be used for vertical conveying of small particle materials in various industries In addition to lifting materials from bottom to top, it can also perform drying and cooling functions on materials. Separate groove type and closed type structures, and design screening elevators for material particle grading and elevators for flammable and explosive materials according to the requirements of different processes.

Motor vibration hoist is widely used in industries such as chemical, rubber, plastic, pharmaceutical, light industry, food, metallurgy, building materials, mining, and grain.

Working principle of motor vibration hoist:

The motor vibration hoist is composed of a lifting groove, a vibration motor, a vibration reduction system, and a base. This series of elevators uses a vibration motor as the vibration source. Two vibration motors of the same model, fixed on the lifting groove, are installed at a certain angle with their centerlines crossing each other, and rotate in opposite directions in self synchronization. The eccentric block carried by the vibration motor generates a centrifugal force component at various instantaneous positions during rotation, which moves back and forth along the throwing direction, causing the entire body supported on the shock absorber to vibrate continuously. The material is thrown up in the lifting groove while moving upward. After falling into the feeding groove, the material begins to be thrown up. At this time, the material can fully contact with the air and also play a role in heat dissipation and cooling. This elevator can vertically transport solid materials in powder, block, and short fiber forms (excluding those with viscosity and easy clumping), and can also complete the drying and cooling of materials. There are two types of structures: open and closed. And special designs can be made according to user needs.

Types of electric vibration hoist:

1. Vibration source classification:

a. Cross axis spiral vibration conveyor. b. Parallel axis spiral vibration conveyor.

2. The above two types are further divided into:

a. Seat type screw conveyor. b. Suspended screw conveyor.

Main features of electric vibration hoist:

1. Small footprint, simple and reasonable structure.

2. Low power consumption, no noise, and easy maintenance.

3. Closed lifting effectively prevents dust and harmful gases from polluting the working environment.