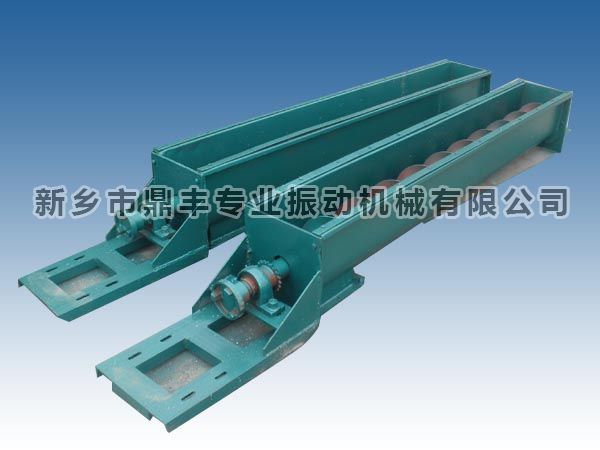

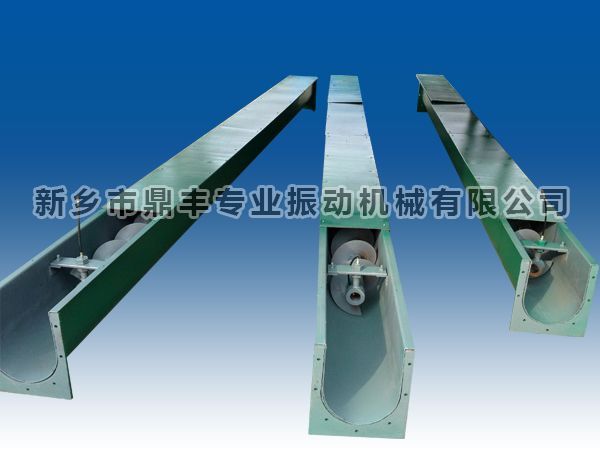

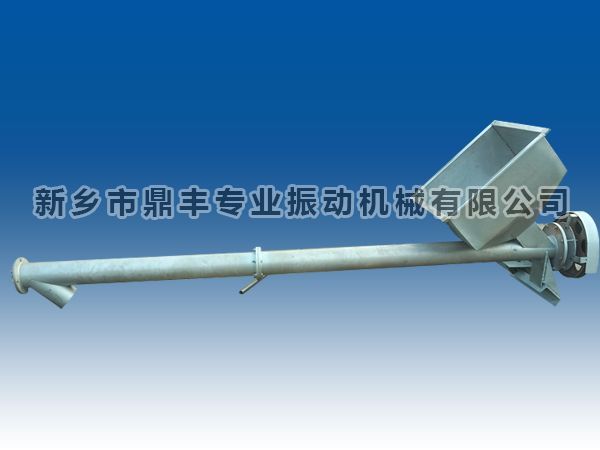

The LS type screw conveyor is designed and manufactured according to the JB/T679-95 standard for screw conveyors, and is a replacement product for the GX type screw conveyor. Spiral conveyors, commonly known as winches, are widely used conveying equipment in the mineral, feed, grain and oil, and construction industries. From the perspective of material displacement direction, spiral conveyors are divided into two types: horizontal and vertical. They are mainly used for horizontal conveying and vertical lifting of various loose materials such as powders, granules, and small blocks. Spiral conveyors are all made of steel and are used to transport chemical and building materials such as powders or solid particles at high temperatures. The interior of the screw conveyor has a conveying pipe, and the blades are welded in a spiral shape on the conveying pipe.

The rotating spiral blades push the material to be transported by the spiral conveyor, and the force that prevents the material from rotating together with the spiral conveyor blades is the weight of the material itself and the frictional resistance of the spiral conveyor housing to the material. The spiral blades welded on the rotating shaft of the screw conveyor have different surface types depending on the conveyed material, including solid surface type, belt surface type, and blade surface type. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction to provide axial reaction force to the screw along with the material. When the machine is long, an intermediate suspension bearing should be added.

The rapid development of screw conveyors is inseparable from the following aspects: on the one hand, the diversification of functions and the expansion of application scope of screw conveyors, such as high angle belt conveyors, tubular conveyors, spatial turning conveyors, and other models are complete; On the other hand, the development of technology and equipment for screw conveyors has become increasingly mature, such as long-distance, large capacity, and high belt speed, which have become the main directions of development; The core technology is the development and application of dynamic analysis and monitoring technology for screw conveyors, which improves the operational performance and reliability of screw conveyors. At present, the spiral conveyor used in coal mines has reached the main technical indicators shown in Table 1, and its key technologies and equipment have the following characteristics:

⑴ Large scale equipment. Its main technical parameters and equipment are developing towards large-scale production to meet the needs of high-yield, high-efficiency and intensive production with an annual output of 3 to 5 million tons.

⑵ By applying dynamic analysis technology, mechatronics integration, computer monitoring and other high-tech, and adopting high-power soft start and automatic tensioning technology, the conveyor is dynamically monitored and monitored, greatly reducing the dynamic tension of the conveyor belt. The equipment has good operating performance and high transportation efficiency.

⑶ By adopting technologies such as multi machine drive, intermediate drive, power balance, and conveyor directional operation, the length of single machine operation of the conveyor is theoretically limited, and the universality, interchangeability, and reliability of the unit drive of the conveying system equipment are ensured.

New and highly reliable key component technology. Various high-power drive devices and speed control devices, including CST, high life high-speed rollers, self-cleaning drum devices, high-efficiency belt storage devices, and fast self moving machine tails. The FSW1200/(2-3) × 400 (600) working face spiral conveyor produced by FSW in the UK adopts liquid viscosity differential speed or variable frequency speed regulation device, with a transport capacity of over 3000 t/h. Its tail is matched with a new type of transfer machine (such as S500E produced by Joy Company in the United States), which can automatically and quickly move with the movement of the working face, with less manual operation and high production efficiency.