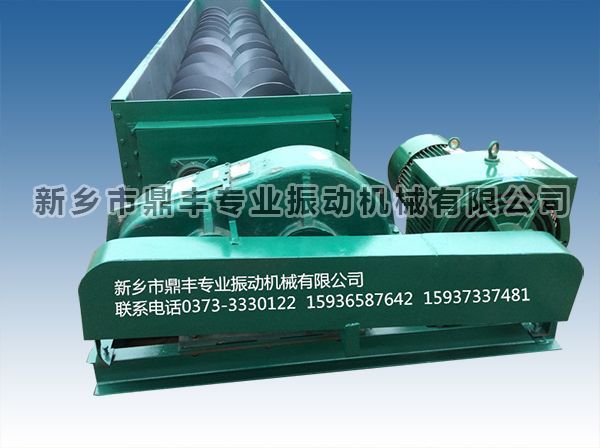

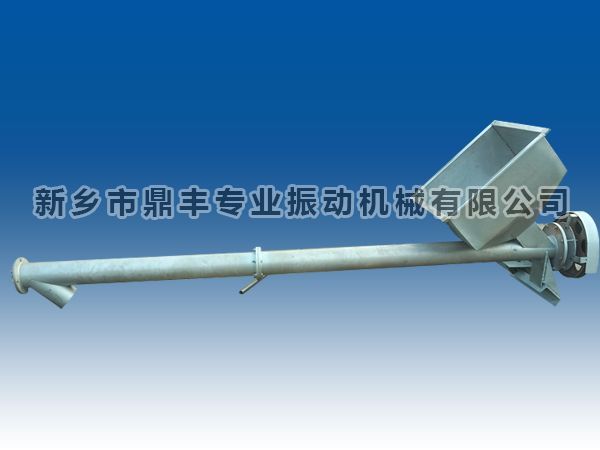

The dual axis mixer utilizes the synchronous rotation of two symmetrical spiral shafts to transport dry ash and other powdery materials while adding water for mixing, uniformly humidifying the dry ash powdery materials, achieving the goal of preventing the humidified materials from emitting dry ash and not leaking water droplets, thus facilitating the transportation of humidified ash onto trucks or transferring it to other conveying equipment.

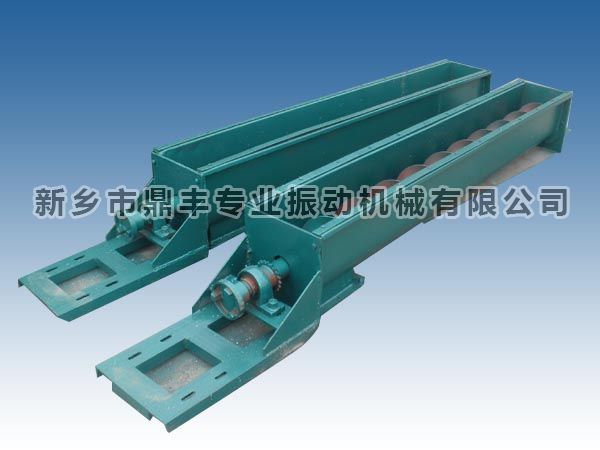

The double shaft mixer is mainly composed of components such as the casing, screw shaft assembly, drive device, piping, cover plate, chain cover, etc

The specific structural performance characteristics are as follows:

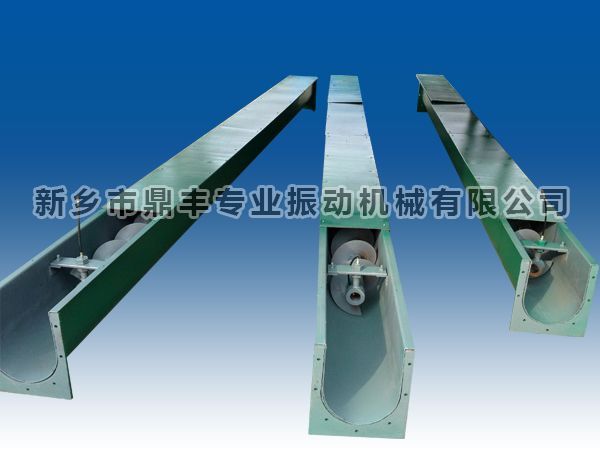

1. The shell is mainly composed of plates and steel sections, welded and formed in the manufacturing plant, and assembled with other components to support the double axis mixer. The shell is tightly sealed, and there will be no flying ash or leakage.

2. The spiral shaft assembly is the main component of a dual axis mixer, which mainly includes left and right spiral shafts, bearing seats, bearing sleeves, bearing covers, gears, sprockets, oil cups, blades, and other components. The manufacturing accuracy of left and right spiral shafts requires high precision, good process performance, and strict fit requirements with bearing seats, bearing sleeves, and bearing covers. The gear module is 8, the number of teeth is 60, and the tooth profile angle is 20 °; The sprocket pitch is 50.8, the number of teeth is 25, and the tooth profile is GB1224-85. Gears and sprockets are protected by protective covers, ensuring safe and effective operation. The oil cup is a press fit injection oil cup, which is convenient and effective for adding lubricating oil. The material for the blades of the dual axis mixer is composite ceramics that are wear-resistant and not prone to sticking to dust. The blade structure design is reasonable and simple, easy to replace after wear, and has a long service life.

3. The water and humidity control piping mainly consists of connecting pipes, joints, and nozzles. The nozzle adopts a stainless steel atomizing cone nozzle, which is arranged above the mixer casing and arranged axially along the spiral axis to form a water curtain for the humidification and mixing of materials. The nozzle structure is simple, easy to replace, made of stainless steel material, corrosion-resistant and durable. The moisture content of wet ash can be adjusted by operating the manual regulating valve on the water supply pipeline.

4. The cover plate mainly includes left cover plate, middle cover plate, right cover plate, hole cover, and maintenance hole cover. There are six inspection holes on both sides of the double shaft mixer for easy maintenance and upkeep by operators.