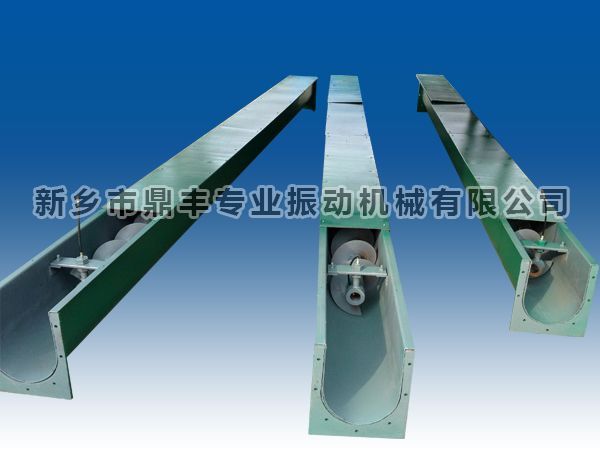

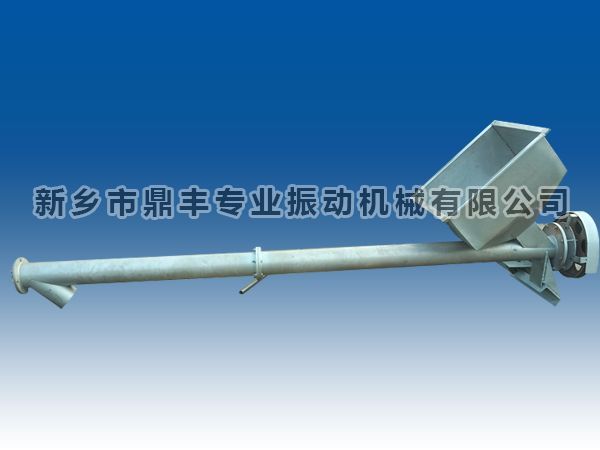

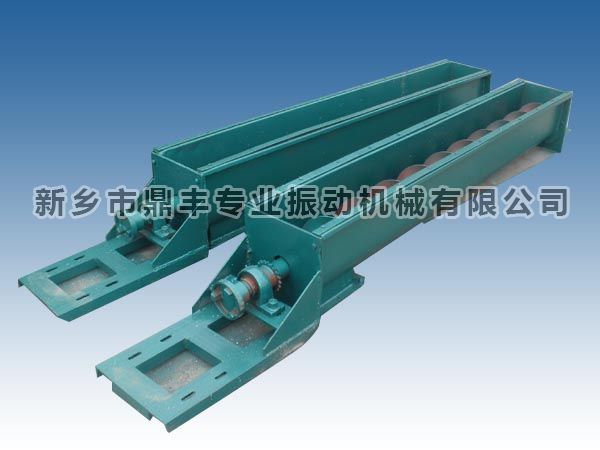

Spiral conveyors, commonly known as winches, are widely used conveying equipment in the mineral, feed, grain and oil, and construction industries. From the perspective of material displacement direction, spiral conveyors are divided into two types: horizontal and vertical. They are mainly used for horizontal conveying and vertical lifting of various loose materials such as powders, granules, and small blocks

Application scope:

Spiral conveyor is the main unit for mechanized transportation in various sectors of industry and agriculture, which can reduce labor intensity and improve work efficiency. It has a wide range of applications Suitable for various industries such as building materials, chemical industry, power, metallurgy, coal, grain, etc. It is suitable for horizontal or inclined transportation of powdery, granular, and small block materials such as coal, ash, slag, cement, grain, etc. The material temperature is less than 200 ℃ Spiral machines are not suitable for conveying materials that are prone to deterioration, high viscosity, and clumping

If the conveying inclination angle is too large, please choose the GX series screw conveyor, or directly contact our technical department for separate design

Disadvantages:

Pipe type screw conveyors are not suitable for conveying materials that are prone to deterioration, high viscosity, and easy agglomeration, because these materials will adhere to the screw during transportation and rotate without moving forward or form material blockages at the suspension bearings, which will prevent the screw machine from working properly. The LS type spiral machine has five specifications for spiral diameters ranging from 200 millimeters to 500 millimeters, with lengths ranging from 4 meters to 70 meters, with one step every 0.5 meters. When selecting, the standard nominal length should be met, and special requirements can be separately stated in the optional section.

characteristic:

1. High load-bearing capacity, safe and reliable

2. Strong adaptability, easy installation and maintenance, long service life

3. The whole machine has a small volume, high speed, and ensures fast and uniform conveying

4. The discharge end is equipped with a cleaning device, which has low overall noise and strong adaptability. The layout of the inlet and outlet positions is flexible

5. Good sealing performance, the shell is made of seamless steel pipe, and the ends are connected to each other with flanges to form a whole, with good rigidity