brief introduction

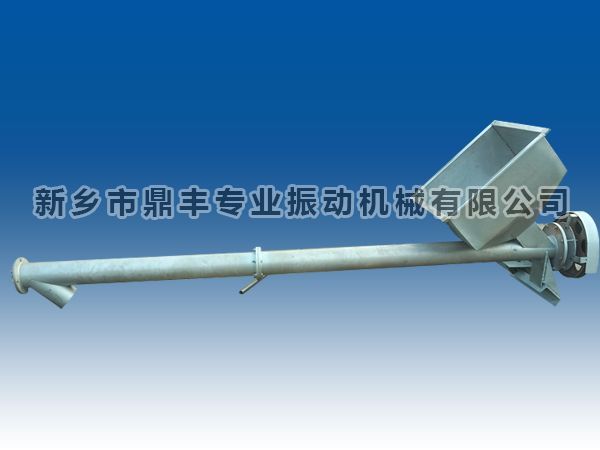

The principle of a double axis screw conveyor is to install a solid screw inside two seamless steel pipes, one of which is left-handed and the other is right-handed. During operation, two spirals rotate by meshing with a pair of gears at the shaft extension position. Due to the rotation of the spiral body, the material moves axially, thereby achieving the conveying purpose.

scope of application

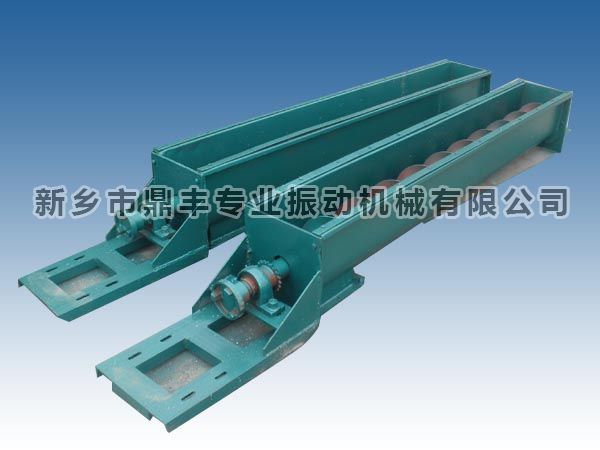

Double axis screw conveyor is a continuous conveying equipment widely used in metallurgy, building materials, chemical industry, grain and mechanical processing departments.

Structural characteristics

1. The connection between the spiral shaft and the suspension bearing, as well as the head and tail shafts, adopts an embedded tongue type, which does not require axial movement for installation and disassembly, making maintenance convenient. The core shaft is long, there are few hanging parts, and there are few fault points.

2. Adopting a variable diameter structure to increase the volume of the suspension bearing and avoid contact between the suspension bearing and the material, the service life of the suspension bearing can reach more than two years.

3. Each transmission part adopts a floating connection method, and the suspension bearing is a universal structure, which forms a whole rotating and floating body with the spiral body, suspension bearing, and tail. Within a certain range, it can freely rotate and avoid resistance, without jamming or blocking materials.

4. The head and tail bearing seats are both located outside the housing, and all bearings use multi-layer sealing boxes with sealing technology, resulting in a long service life of the bearings.

Compared with other conveying equipment, it has the advantages of small overall cross-sectional size, good sealing performance, stable and reliable operation, multi-point loading and unloading in the middle, safe operation, and simple maintenance.