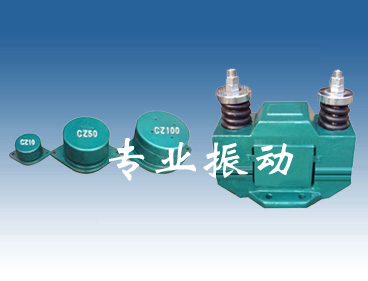

1、 Purpose and Characteristics

The silo wall vibrator is used to prevent and eliminate various phenomena such as "blockage" and "arching" caused by internal friction, deliquescence, electrification, and component segregation of materials in the silo. It is a good auxiliary equipment for the smooth discharge of materials from the silo mouth, ensuring the normal operation of the entire production process. It is widely used in various industries such as mining, metallurgy, chemical engineering, building materials, and machinery.

The CZ type silo wall vibrator, due to the use of near resonance principle, has the characteristics of small size, long service life, low power consumption, simple structure, and easy installation. Compared with the methods of adding stirring wings, sending pulsating compressed air, etc. to relieve "blockage" and "arching", it has the advantages of low equipment cost and small maintenance.

The CZ type silo vibrator will significantly reduce its ability to break the arch of viscous materials.

2、 Main technical parameters

型号 | 振动力 kgf | 适用料仓壁厚 mm | 电压 V | 有功功率w | 表示电流 A | 振动次数 次/分 | 重量 kg | 配套控制箱 型号 |

CZ10 | 10 | 0.6~0.8 | AC220 | 20 | ≤0.3 | 3000 | 2.6 |

XKZ—5G2 |

CZ25 | 25 | 0.8~1.6 | 25 | ≤0.4 | 8 | |||

CZ50 | 50 | 1.2~1.6 | 30 | ≤0.5 | 10 | |||

CZ100 | 100 | 1.5~4.0 | 40 | ≤0.9 | 15 | |||

CZ150 | 150 | 2.0~0.8 | 50 | ≤1.0 | 17 | |||

CZ250 | 250 | 4~8 | 60 | ≤1.2 | 35 | |||

CZ400 | 400 | 6~10 | 120 | ≤2.0 | 62.5 | |||

CZ600 | 600 | 6~12 | 150 | ≤2.3 | 70 | XKZ—10G2 | ||

CZ800 | 800 | 6~14 | 200 | ≤3.8 | 90 | |||

CZ1000 | 1000 | 8~14 | 200 | ≤3.8 | 100 | |||

CZ1500 | 1500 | 10~16 | 300 | ≤7.0 | 120 | XKZ—20G2 |

注:适于安装料仓壁厚数值仅供参考。

三、主机外型尺寸

外型尺寸如图:图〔2〕为CZ250、CZ400、CZ600、CZ800、CZ1000、CZ1500型螺旋弹簧仓壁振动器,图〔1〕为CZ10、CZ25、CZ50、戏100、CZ150型为环氧旋弹板簧仓壁振动器,图〔3 〕为CZ250、CZ400、CZ600可制作成封闭型仓壁振动器

单位:mm

型 号 | L1 | L | B1 | B | h | H | D | n-фd | 图形 |

CZ10 | 146 | 183 | 138 | 6 | 96 | ф120 | 2—ф10 | 图1 | |

CZ25 | 245 | 240 | 178 | 8 | 120 | ф170 | 2—ф12 | ||

CZ50 | 250 | 270 | 185 | 8 | 128 | ф180 | 2—ф13 | ||

CZ100 | 250 | 280 | 185 | 10 | 165 | ф195 | 2—ф14 | ||

CZ150 | 260 | 285 | 190 | 10 | 170 | ф195 | 2—ф14 | ||

CZ250 | 230 | 400 | 145 | 170 | 15 | 300 | / | 4—ф12 | 图2 |

CZ400 | 230 | 400 | 210 | 245 | 16 | 360 | / | 4—ф14 | |

CZ600 | 230 | 400 | 210 | 245 | 16 | 360 | / | 4—ф14 | |

CZ800 | 120 | 550 | 230 | 346 | 23 | 400 | / | 4—ф26 | |

CZ1000 | 120 | 550 | 230 | 346 | 23 | 400 | / | 4—ф26 | 图2 |

CZ1500 | 220 | 560 | 240 | 346 | 23 | 420 | / | 4—ф20 |

working principle:

As shown in Figure (2), the warehouse wall vibrator is composed of vibrating body, resonant spring, electromagnet, base and other components. Vibration

The vibrating mass m1 is composed of components such as the moving body, iron core, and coil, which together with the main vibrating spring form a single body near resonance system. electromagnetism

The coil is powered by alternating current through a half wave rectification circuit and generates electromagnetic force, causing the system to vibrate under forced force. Vibration

The inertia force of the moving mass m1 is transmitted to the warehouse wall through the auxiliary spring, causing slight vibration of the warehouse wall and effectively overcoming the material

The internal friction and cohesion of the material enable it to be smoothly discharged from the hopper mouth.

4、 Maintenance and Debugging

When the machine is working normally, it should meet the following standards:

1. The current does not exceed the rated value;

2. The amplitude of the vibrating body (shell) reaches or exceeds the rated value of 1.7mm;

3. There is no abnormal noise during vibration, generally less than 40-50 decibels.

If the machine malfunctions, it should be stopped for maintenance in a timely manner to avoid damaging other components.

Common faults and maintenance methods

故 障 征 象 | 可 能 原 因 | 排 除 方 法 |

振动器无振动 | 1、 电控箱无电流输出。 2、 连接线断路。 3、 线圈损坏。 | 1、 检查电控箱及电源。 2、 检查联接各接点是否断开。 3、 更换线圈。 |

振动微弱电流偏大 | 1、弹簧刚度偏大或偏小。 2、气隙偏大或堵塞。 3、输出电压低。 | 1、调整弹簧刚度或配重重量。 2、调整气隙。正常值2.5±0.1mm。 3、检查电控箱及电源。 |

噪 音 | 1、弹簧压紧螺栓或配重螺栓松开。 2、弹簧断裂。 3、仓壁共振。 4、电磁铁撞击。 5、振动器底脚松动。 | 1、压紧螺栓。 2、更换相同尺寸、相同厚度、相同数量的环氧玻璃钢弹簧。 3、调整仓壁刚度或加入物料。 4、调低电控箱输出电压。 5、压紧振动器固定底脚螺栓。 |

Debugging method:

The vibrator generally operates in a bottom critical near resonance state. The stiffness of the spring directly affects the working state of the vibrator. As the stiffness increases, the amplitude decreases and the current increases; The stiffness decreases, the amplitude becomes unstable, the current increases, and it may also cause collisions between the electromagnets. Specific debugging method: When the stiffness is high, you can slightly loosen the compression bolts at both ends of the spring or increase the weight of the counterweight on the vibrating body; When the stiffness is low, the plate spring can be compressed to tighten the bolt or reduce the weight of the counterweight.

5、 Usage method