purpose

A vibration motor is an excitation source that combines a power source and a vibration source. The vibration motor is equipped with a set of adjustable eccentric blocks at each end of the rotor shaft, and uses the centrifugal force generated by the high-speed rotation of the shaft and eccentric blocks to obtain the excitation force. The vibration motor has high utilization rate of excitation force, low energy consumption, low noise, and long service life. The excitation force of the vibration motor can be infinitely adjusted, making it easy to use. Models such as JZO, YZU, YZO, YZS, YZD, TZDC, etc. are universal vibration motors. Vibration motors can be applied to general vibration machinery, such as vibration crushers, vibration screening machines, vibration packers, vibration sand falling machines, vibration molding machines, vibration pile drivers, vibration hoists, vibration filling machines, vibration arch breaking and anti blocking devices for silos, and so on. Widely used in industrial sectors such as hydropower construction, thermal power generation, construction, building materials, chemical industry, mining, coal, metallurgy, and light industry.

In addition to being applied to general vibration machinery, vibration motors can also be combined with various forms of vibration. For example: flat spiral type, vortex type, shaking vibration type, combined linear type, combined long elliptical type, composite dual frequency type, composite dual amplitude type, etc. These vibration forms can generate some new types of vibration machinery that were not available in the past.

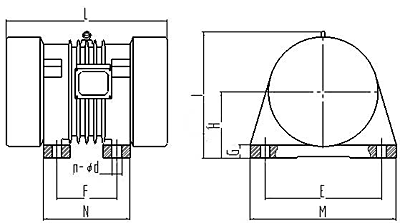

Outline dimension diagram:

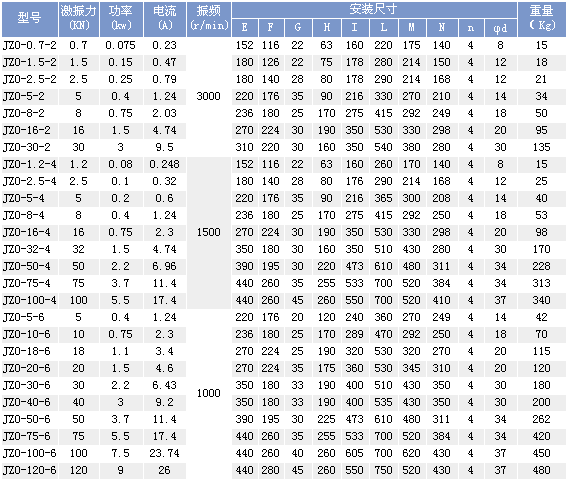

Main specifications and technical parameters