Purpose and characteristics

The KZS series mining vibrating screen adopts domestic and foreign technologies such as vibration motor excitation, steel spring or rubber spring vibration reduction, wear-resistant material sieve plate (screen), sealed or open screen box, and self synchronous vibration principle. Featuring long lifespan, low noise, and high screening efficiency, it is suitable for high-energy screening of sintered ore, natural ore, coke, and other granular materials. It has been widely used in industries such as metallurgy, mining, coal, building materials, refractory materials, and grain.

Working principle and structural characteristics

The screening body relies on two identical vibration motors to rotate in opposite directions in self synchronization, allowing the entire screening machine to vibrate linearly under the support of damping springs. After the material falls into the screening box from the feeding end, it quickly advances, loosens the mesh, and completes screening.

The vibrating screen consists of a screen box, a vibration motor, a vibration reduction system, and a base. The sieve box is composed of a sieve frame, sieve plate (mesh), lining plate (mesh), etc.

The screening machine adopts the high-performance and long-life YZD series vibration motor as the excitation source. The amplitude of the screening machine is achieved by adjusting the excitation force of the vibration motor. The adjustment method can be found in the YZD series vibration motor manual.

The vibration reduction system consists of springs, clamps, support seats, etc. The installation methods of vibration motors for this series of vibrating screens can be divided into upper vibration type, lower vibration type, and side vibration type. The installation methods of shock absorbers can be divided into seat type and hanging type. Special design and manufacturing can also be carried out according to user needs.

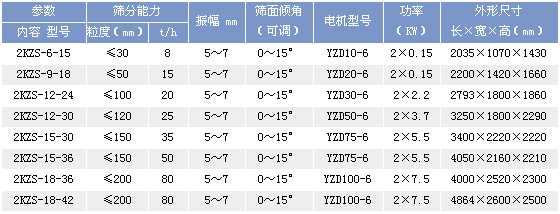

Main specifications and technical parameters

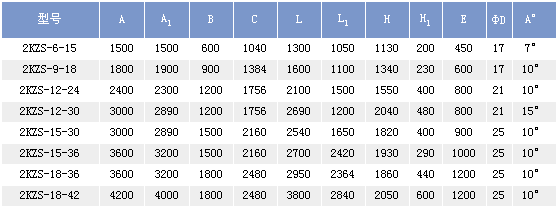

Note: The screening capacity in the table is calculated based on a yellow sand specific gravity of 1.6t/m3; The dimensions in the table are the size of the 2-layer sieve pattern, and the height H of the single-layer sieve has been reduced by 100mm.

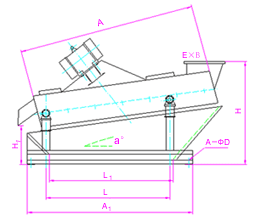

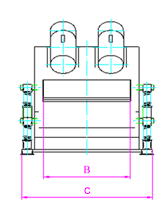

Outline dimension diagram

Dimensions

install and adjust

1. The chassis is fixed on the foundation, so that the height difference between the front and rear support seats on the same side is consistent. The support seat plates on both sides of the same end (feeding end or discharging end) are in the same horizontal plane, and the error is within 2mm.

2. Choose springs with the same (or similar) stiffness to be configured at different support positions on the same vibrating screen. At this time, the height of the springs at each support point should be the same, and the error should not exceed 2mm.

When it is necessary to adjust the inclination angle of the screen surface, the fixing bolts of the clamps can be loosened, the upper support seat can be rotated, and the rear support seat can be raised (or lowered) at the same time. Adjust the distance between the front and rear support seats to make the inclination angle of the screen surface meet the requirements for use.

4. The connection of each part of the screening machine must be firm and reliable, and all bolts must not be loose. There must be no abnormal noise from any components. The small gap between the vibrating part on the screening machine and the surrounding fixed objects is 30-50mm.

When the screening machine leaves the factory, the double amplitude is adjusted to 6-8mm. During use, users can adjust the angle between the main and auxiliary eccentric blocks of the vibration motor according to their needs, change the magnitude of the excitation force, and then adjust the amplitude of the screening machine.

use and maintenance

Before starting the screening machine, it is necessary to check whether there are any obstacles that hinder the operation of the screening machine, whether the connecting bolts are tightened, and whether the fixing bolts should be tightened multiple times, especially for the fixing bolts of the vibration motor, support seat, and screen plate.

2. Check if the two vibration motors have opposite directions. If they have the same direction, change the power wiring of one motor to make the two vibration motors have opposite directions.

3. When the screening machine is running, start, run, and stop it with no load for one to two times to observe for any abnormal phenomena or sounds, ensuring smooth and normal operation.

After running continuously for 4 hours, measure the bearing temperature, which should not exceed 75 ° C; and re tighten the connecting bolts of each part, and regularly tighten them in the future.

When screening materials, the feeding should be uniform, so that the materials are evenly distributed on the screening surface. If the materials "deviate", the feeding point should be adjusted.

Before stopping the screening machine, the feeding should be stopped first, and the machine should be stopped only after the screening surface material has been removed. After stopping the machine, it is necessary to promptly clean the materials and debris on the screen surface to prevent the mesh from sticking and blocking.

7. The vibration motor should be refueled after 3 months of use, undergo minor repairs every six months, and undergo major repairs every year. The vibration motor should be maintained and serviced according to the YZD series vibration motor manual.