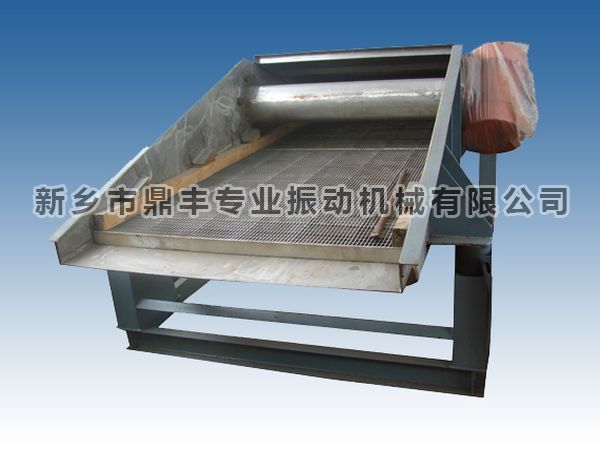

XZST dewatering screen is an efficient coal slurry separation dewatering screen used in coal preparation plants for the coal industry. The SZD dewatering vibrating screen moves in a straight line and is produced according to the JB2444-86 "ZSM coal bed double axis vibrating screen" standard. There are a total of sixteen specifications in the entire series, which can be used in industrial sectors such as coal preparation, mineral processing, power generation, sugar production, and salt production to perform dry wet screening, dewatering, media removal, and sludge removal on medium and fine-grained materials.

The main features of XZST series dehydration are:

1. Low noise and easy maintenance.

2. Reasonable structure, sturdy and durable.

3. Good dehydration effect, safe and reliable.

4. Large screening processing capacity and high screening efficiency.

5. Lightweight, easy to disassemble and assemble, convenient for maintenance, and no sudden segment springs

Working principle of XZST series dehydration:

The XZST dewatering screen adopts dual electrode self synchronization technology and a universal fast eccentric, adjustable amplitude vibrator. By using adhesive tape to drive two unrelated vibrators to operate synchronously and in reverse, the centrifugal force generated by the two sets of eccentric masses along the vibration direction is superimposed, and the reverse centrifugal force cancels out, thus forming a single excitation vibration along the vibration direction, causing the sieve box to move back and forth in a straight line.

XZST series dehydration technology parameter table:

型号 | 筛面面积 | 网孔尺寸 | 筛网 | 给料粒度 | 处理量 | 振次 | 双振幅 | 电机功率 | 振动方向角 | 外形尺寸 |

XZST-926 | 2.34 | 0.25-50 | 编织 | ≤150 | 1.5-100 | 960 | 6-10 | 2×1.5 | 45 | 2740×1340×1520 |

XZST-1030 | 3 | 2-120 | 8-10 | 2×2.2 | 3140×1440×1680 | |||||

XZST-1230 | 3.6 | 3-180 | 8-10 | 2×2.2 | 3140×1640×1680 | |||||

XZST-1540 | 6 | 5-250 | 8-12 | 2×3.0 | 4140×1940×1790 |

User purchase tips:

When selecting and ordering, users should indicate the mesh structure (weaving, punching, seam), mesh size, processing capacity, material name, and feeding particle size.

SZD Dehydration Screen Ordering Notice:

When selecting and ordering, the arrangement of the sieve and the size of the sieve gap should be determined. If not determined, the supply should be arranged according to the right-hand pattern with a gap of 0.5 millimeters (the motor is located on the left or right side of the material flow direction).

2. The inclination angle of the screen surface can be adjusted within -2 to 10 degrees Users can adjust themselves by choosing other angles.

When using synchronization, the motor should be installed on the left and right sides, and this should be specified when ordering.