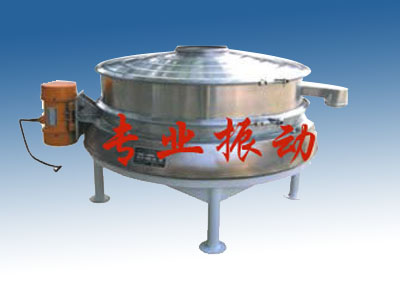

Direct screening is a new type of screening machine designed by our company's technical personnel, which changes the original dual motor structure and adopts a single horizontal vibration motor. The material's running trajectory has multiple adjustment forms, and the equipment's adaptability is significantly increased; Direct discharge of materials has a large processing capacity. ZZM-1000 screening machine, with a mesh size of 24 mesh, is used for online screening and manufacturing of wheat flour for instant noodles. It is used for impurity removal and increasing the specific surface area of wheat flour, and can reach 140KG/min.

Widely used for rough screening and precision screening of granular powders in industries such as flour, starch, laundry detergent, metal powder, additives, chemical, and non mineral, with large processing capacity and easy integration with production lines. You can have more choices between 600mm and 1800mm.

Function and principle of direct screening:

The working principle of the direct screening is to use two sets of eccentric blocks (unbalanced eccentric blocks) at the upper and lower ends of the vibration motor shaft to convert the rotational motion of the vibration motor into multiple overlapping forces of horizontal, vertical, inclined, and centrifugal effects. Then transfer this force to the sieve surface. Changing the phase angle and weight of the upper and lower eccentric blocks can alter the magnitude of the excitation force and the trajectory of the material's movement.

Characteristics of direct screening:

*All stainless steel design, beautiful and durable appearance.

*Small in size, space saving, and easy to move.

*Low energy consumption and high efficiency.

*Easy to disassemble and assemble, easy to clean both inside and outside, no hygiene dead corners, in compliance with food grade GMP standards.

*Automated operation, capable of 24-hour continuous production

*Ultra low noise design.

*Strict sealing, no liquid leakage, and no dust flying.

*Can be used in single or multiple layers, with multiple levels of filtering at once

Main specifications and technical parameters of direct screening:

型号 | 功率 (kw) | 筛面直径 (mm ) | 有效面积(m2 ) | 体积 (mm) |

ZPS-600 | 0.12 | 520 | 0.2124 | 740×600×560 |

ZPS-800 | 0.18 | 720 | 0.4072 | 1010×800×600 |

ZPS-1000 | 0.18 | 890 | 0.6221 | 1200×970×640 |

ZPS-1200 | 0.25 | 1090 | 0.9331 | 1430×1170×700 |

ZPS-1500 | 0.55 | 1390 | 1.5175 | 1780×1470×760 |

Note: To meet the needs of individual industries or users, there are various types of designs, such as edge added, gate type, baffle type, spray type, etc. And accept customization of external dimensions according to specifications.