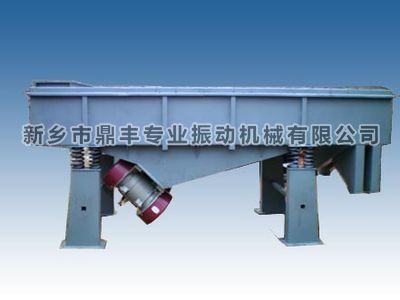

The linear vibrating screen is collectively referred to as DZSF type, commonly known as the abbreviation for linear screen or ZDSF type. As a form of screening, the linear vibrating screen has a wider range of applications and higher output. It can simultaneously screen 7-8 different materials and is the preferred equipment for screening machines

Principle of Linear Vibration Screen

A linear vibrating screen uses two vibration motors as vibration sources. When the two vibration motors rotate synchronously and in reverse, the excitation force generated by their eccentric blocks cancels each other out in the direction parallel to the motor axis, and forms a combined force in the direction perpendicular to the motor axis. Therefore, the motion trajectory of the screen machine is a straight line. The two motor shafts have an inclination angle relative to the screen surface. Under the combined force of excitation force and material self gravity, the material is thrown up on the screen surface and undergoes a jumping forward linear motion, thereby achieving the purpose of screening and grading the material

Characteristics of Linear Vibration Screen

The linear vibrating screen can be designed with the discharge position and number of layers of the screen surface according to its non-standard type, with a maximum height of 7 layers and 8 discharge ports

Technical parameters of linear vibrating screen (for reference only, can be designed according to different production capacities of customers)

Note: Due to the non-standard type of linear sieve, there are various models such as 12301235124012451530153515401545, which can also be customized with different widths and lengths. The material is carbon steel or stainless steel, and the number of layers can be customized from 1 to 7

Direct leakage linear vibration

Catalyst linear vibrating screen(1235)

Hook plate linear vibrating screen